ABOUT US

ABOUT US

ABOUT US

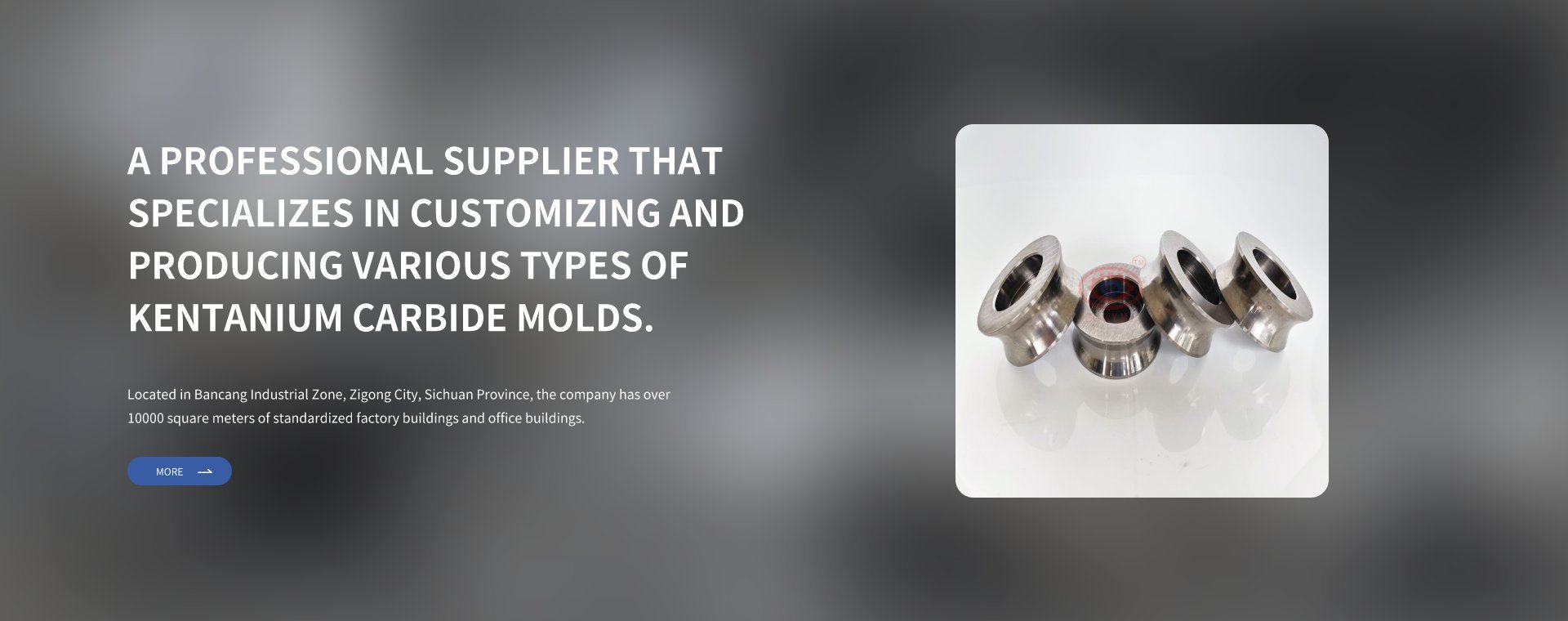

XINGYU CEMENTED CARBIDE DIES&TOOLS

Focus on cemented carbide parts and die manufacturing

Zigong Xingyu Cemented Carbide Dies&Tools Co..Ltd is a professional supplier of tungsten carbide and all kinds of customized tungsten carbide wearparts. Which integrates Research & Development, Production, Marketing and Services. Our company was founded in 1999 and located in Zigong city, Sichuan province of China. We have more than 20 years experience in researching and manufacturing of tungsten carbide products such as carbide molds&dies, bushings, valve seats, nozzles, inserts & cutting tools. carbide rods and bars, carbide plates & strips and other customized tungsten carbide wear parts etc.

With high-purity cemented carbide raw materials, we can produce various products as per customer special requirements. OEM / ODM are both welcome. With high-tech equipment and strict quality test system, we have won a good reputation of high quality in both domestic and overseas market. Our tungsten carbide products have been exported to many countries around the world. Being reliable and professional is our value of service. Providing customers with high satisfaction services and high quality products is always our mission.

Sincerely welcome the friends all over the world to contact us for a WIN-WIN cooperation!

Incorporation

Active employees

National qualifications

Cooperative partner

PRODUCTS CENTER

COMPREHENSIVE, HIGH-QUALITY, AND FAST

TESTING METHODS

device pulsation testing

micro-hardness testing

surface roughness testing

metallography analysising

dynamic balance testing

INDUSTRY SOLUTIONS

OEM / ODM are both welcome

With high-purity cemented carbide raw materials, we can produce various products as per customer special requirements

NEWS AND INFORMATION

Unleashing the Power of Tungsten Carbide Valve Cores in Mining Machinery

Unleashing the Power of Tungsten Carbide Valve Cores in Mining Machinery Table of Contents 1. Introduction to Tungsten Carbide Valve Cores 2. Understanding the Importance of Valve Cores in Mining Machinery 3. The Unique Properties of Tungsten Carbide 3.1 Hardness and Wear Resistance 3.2 Corrosion Resistance 3.3 Thermal Stability 4. Applications of Tungsten Carbide Valve Cores in Mini

14

2025-09

Understanding Tungsten Carbide Valve Cores: A Key Component in Mining Machinery

Tungsten carbide valve cores are engineered components designed to improve the efficiency and longevity of various machinery used in the mining and mineral processing industries. Composed predominantly of tungsten and carbon, this material is known for its exceptional hardness and wear resistance. These properties make tungsten carbide an ideal choice for high-performance applications where durabi

08

2025-09

Future-proofing Mining Operations: Unlocking the Benefits of Tungsten Carbide Valve Cores

Future-proofing Mining Operations: Unlocking the Benefits of Tungsten Carbide Valve Cores Table of Contents Introduction to Tungsten Carbide Valve Cores Understanding Tungsten Carbide Key Benefits of Tungsten Carbide Valve Cores Durability and Longevity Cost Efficiency Enhanced Performance Environmental Impact Applications in Mining Operations Future Tr

02

2025-09

Understanding Tungsten Carbide Valve Cores in Mining and Material Processing

Tungsten Carbide Valve Cores are vital components in the manufacturing and processing machinery industry, primarily utilized in crushing and sorting machinery, as well as in mining equipment. These valve cores are designed for high durability and resistance to wear, making them ideal for applications that demand reliability under extreme conditions. Tungsten carbide is a composite material that co

27

2025-08

Maximizing Efficiency: The Role of Tungsten Carbide Valve Seats in Industrial Machinery

Maximizing Efficiency: The Role of Tungsten Carbide Valve Seats in Industrial Machinery Table of Contents 1. Introduction to Tungsten Carbide Valve Seats 2. Why Tungsten Carbide Valve Seats Matter in Manufacturing 3. Composition and Properties of Tungsten Carbide 4. Key Benefits of Tungsten Carbide Valve Seats 4.1 Exceptional Durability and Wear Resistance

21

2025-08

The Essential Role of Tungsten Carbide Valve Seats in Mining Equipment

Tungsten Carbide Valve Seats are critical components in various mining and material processing machinery, particularly in crushing and sorting equipment. Designed for high-performance applications, these valve seats are made from a composite material that combines tungsten and carbon, resulting in exceptional hardness and wear resistance. This unique material structure allows Tungsten Carbide Valv

15

2025-08