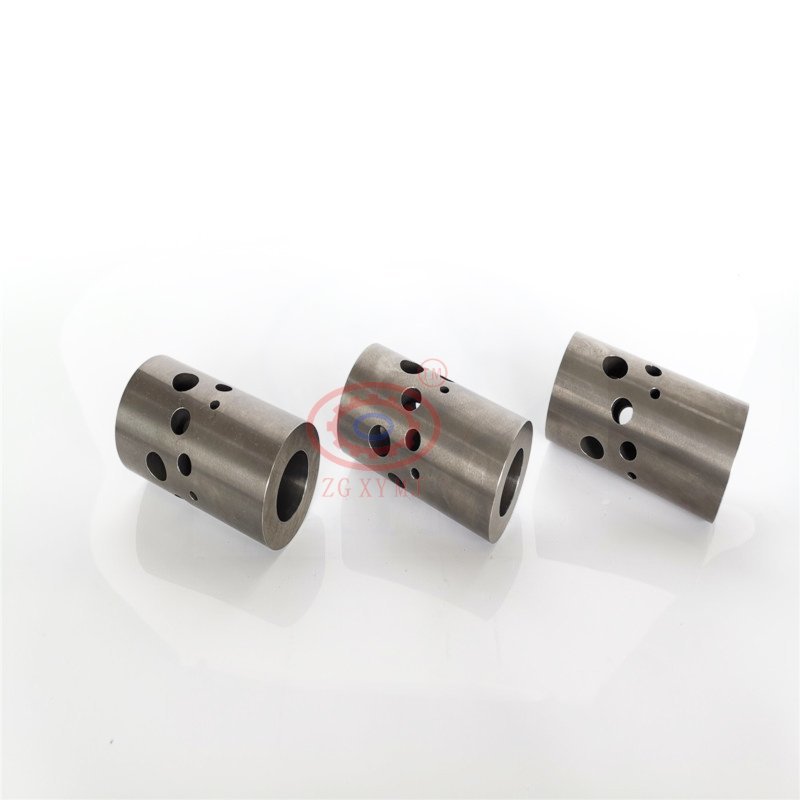

Tungsten carbide dies: a key role in industrial manufacturing

Release time:

2024-07-05

Tungsten carbide dies play an extremely important role in the modern industrial field.

Tungsten carbide dies have many excellent properties. It is extremely hard and can withstand high-intensity pressure and wear, and can still maintain good shape and precision during long-term use. This makes it an ideal choice for manufacturing various precision parts.

Tungsten carbide dies play an indispensable role in the metal processing industry. Whether it is punching, drawing or extrusion, it can ensure high-quality product output. Its high-precision characteristics ensure the consistency and accuracy of product dimensions, meeting the strict requirements of modern industry for high quality.

Tungsten carbide dies also have good heat resistance and corrosion resistance, enabling it to work stably in various harsh environments. Even under high temperature and highly corrosive conditions, it can maintain excellent performance.

However, the manufacturing process of tungsten carbide dies is very demanding. Advanced technology and processes are required to ensure that the quality and performance of the mold are at the optimal level.

When using tungsten carbide dies, reasonable maintenance and care are also required to extend their service life. Regular inspection and cleaning, as well as correct use methods are very important.

Hot News